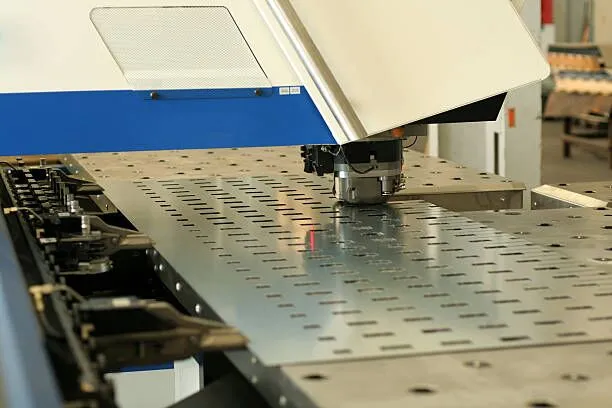

Shaping Metal, Crafting Excellence – Precision You Can Trust

At XINDUX, we offer precision sheet metal fabrication to deliver complex, customized components across industries.

Services Include

Up to 25 mm thickness

Laser Cutting

10–100 tonnes

Power Press

Up to 15 mm

Bending/ Forming

Powder coating, anodizing, plating

Finishing

CNC Punching

MIG, TIG, and Spot Welding

Custom Fabrication & Prototyping

Versatile Sheet Metal Solutions

We offer a wide range of sheet metal processes tailored to meet diverse manufacturing needs, delivering high-quality components with precision, consistency, and cost-efficiency.

Advanced Equipment

Our Capabilities

Materials

From Design to Delivery

We ensure end-to-end quality with optional finishing layer verification and detailed surface reports. Custom coatings and welding-ready parts provided to meet environmental and assembly requirements.

Inspection

Finishing layer verification & surface reporting

Coating

Custom coating for environmental compliance

Delivery

Welding-ready or fully finished parts