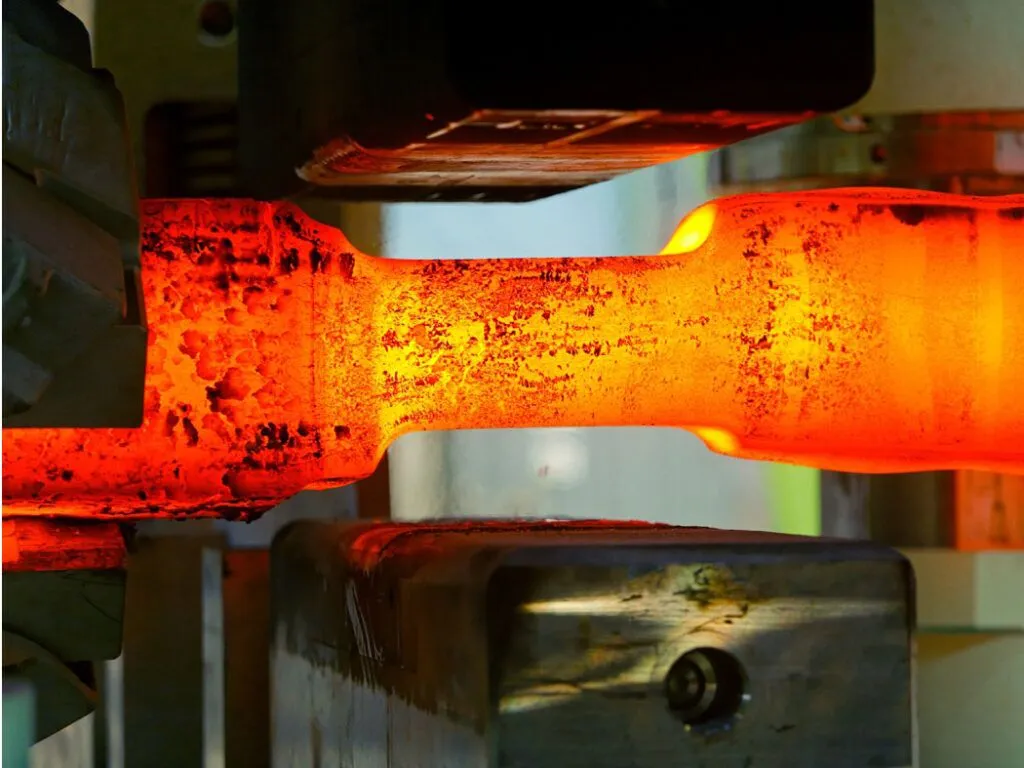

Forging Strength, Crafting Excellence – Powering Innovation with Every Strike

At XINDUX, we deliver high-performance forging solutions for demanding industries including automotive, energy, construction, and heavy engineering.

Precision Highlights

For large, custom parts

Open-Die Forging

High-precision for complex shapes

Closed-Die Forging

Volume production with excellent finish

Cold Forging

Enhanced ductility & reduced machining

Hot/Drop Forging

Versatile Forging Solutions

We offer a wide range of forging processes tailored to meet diverse manufacturing needs, delivering high-quality components with precision, consistency, and cost-efficiency.

Capacity & Equipment

Our Capabilities

Materials

Carbon Steel, Alloy & Stainless Steel, Aluminium, Zinc, Brass, Nickel Alloys, and more

Component Weights

10 g – 15 kg

From Design to Delivery

We ensure end-to-end quality with optional finishing layer verification and detailed surface reports. Custom coatings and welding-ready parts provided to meet environmental and assembly requirements.

Inspection

Finishing layer verification & surface reporting

Coating

Custom coating for environmental compliance

Delivery

Welding-ready or fully finished parts